Disruptions in the supply chain worldwide have made it more important than ever to keep a close eye on optimization opportunities to save time and money. This means making sure resources are being used properly beyond purchasing, logistics, and accounting departments. And it is also about reducing costs when possible.

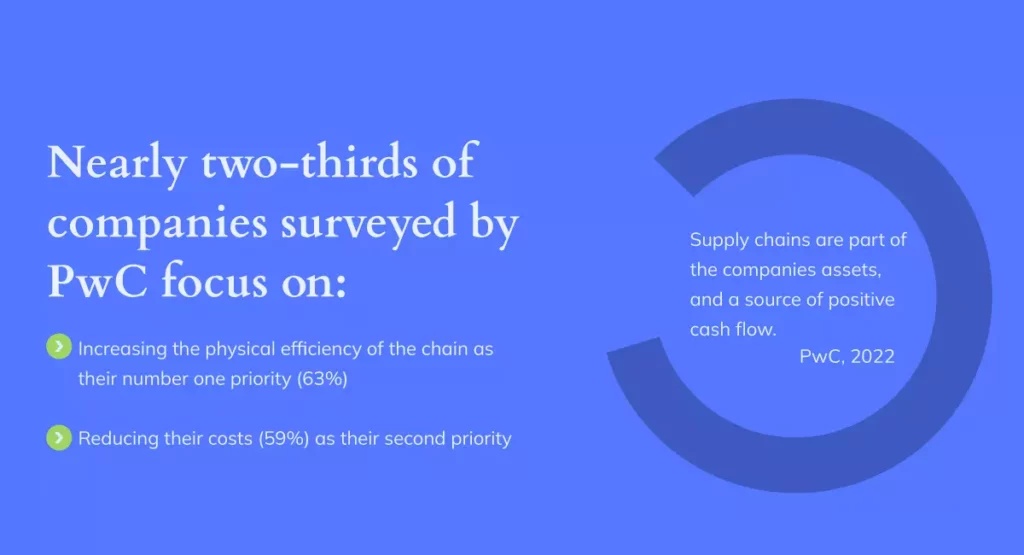

Many analysts are realizing that supply chains can be considered a significant corporate asset. Recent findings from a PWC survey inform that “almost two-thirds of corporate respondents said their number 1 priority was improving the physical efficiency of the supply chain (63%) and reducing its costs (59%).”

These priorities are common but they can lead to strategies that focus on cash flow at the expense of long-term success. A common potential problem is that they can bring short term positive results that can have negative outcomes over the long term.

Money in your supply chain is money in motion

A business needs funds to keep their supply chain functional. Financial resources are needed to acquire raw materials, pay for services from suppliers, and maintain sufficient inventory levels. As a business grows, funding growth and investments can become increasingly complex. Organizations that maximize supply chain capital have an important competitive advantage over others.

Cash flow depends on many factors. One of them is the physical distance between suppliers and buyers. For example, when suppliers are farther away, payment cycle time and negative cash flow tend to increase. Supplies in transit and excess inventory to make up for potential disruptions also tie up company funds. An extension of credit to customers as a marketing strategy has the same effect on the cash inflow side of the cycle.

Supplier relationship philosophy

Unlike larger supplying companies, small and medium-sized (SMB) suppliers are not able to enforce payment terms with larger buyers due to power imbalance. The New York Times says that large companies benefit from “maximizing the use of their capital” by paying out at 120 days (the longest time frame they can negotiate). Also, the author of the article noted that some companies are even going as far as waiting 150 days to make payments. As a result, suppliers pay more in financing costs, and this weakens them. On the other hand, this also impacts and raises market prices for the final consumer.

It is easy to ignore the benefits of good supplier relationships even when they represent positive potentials. Some convenient outcomes include better product quality, more agile processes, and business costs reduction. And yet, many buyers continue to opt for the lowest cost bidder at their own peril.

Harvard Business Review has noted that “partnerships are the supply chain’s lifeblood”. Even so, buyers fail to capture the positive benefits – reducing costs, improving quality, speeding up processes – that good supplier relationships bring to the supply chain. Accenture Consulting claims that better supplier relationship management boosts product value. Buyers need to recognize and treat suppliers as integral assets and forces in their supply chains.

Seller relationships and cash flow methods

Even when most B2B transactions occur on credit, many companies struggle with outdated, misaligned strategies and processes to maximize and speed up payment collections. Financial managers attempt to free the capital locked in supply chains by traditional methods including:

- Use of trade credit

- Invoice finance

- Reverse factoring

- Factoring

- Dynamic discounting

Understanding each of these strategies is critical, but more important is using them in a coordinated, well planned direction that can actually help to optimize the supply chain to save time and money.

Save time and money with a best in class program

According to a McKinsey report, nearly 80 percent of eligible assets remain unaffected by working-capital financing, and the remaining 20 percent are often inefficiently financed. Freeing up the capital absorbed in the supply chain should be a priority to support optimization and to save time and money. Consider these characteristics as part of a best-in-class program:

- A holistic approach that considers the supply chain as a whole.

- Positive supplier relationships that consider supplier’s processes and way of work.

- Technology advantages such as data digitalization or electronic invoicing to facilitate the rapid flow of information between both parties.

- Existing process integration along the supply chain to increase efficiencies, reduce errors, and promote positive relationships.

- Transparency along the supply chain to facilitate information and visibility as an efficiency opportunity. This includes open communications.

- Expanding “supply” networks that act as systems of interlinked suppliers and customers constantly expandings.

How are you planning to optimize your supply chain cash flow?